Order the BS-8 Balancing Stand here. All about Shipping and Payments here. Our YouTube channel is here. Learn about the B-200 Balancing Ring here.

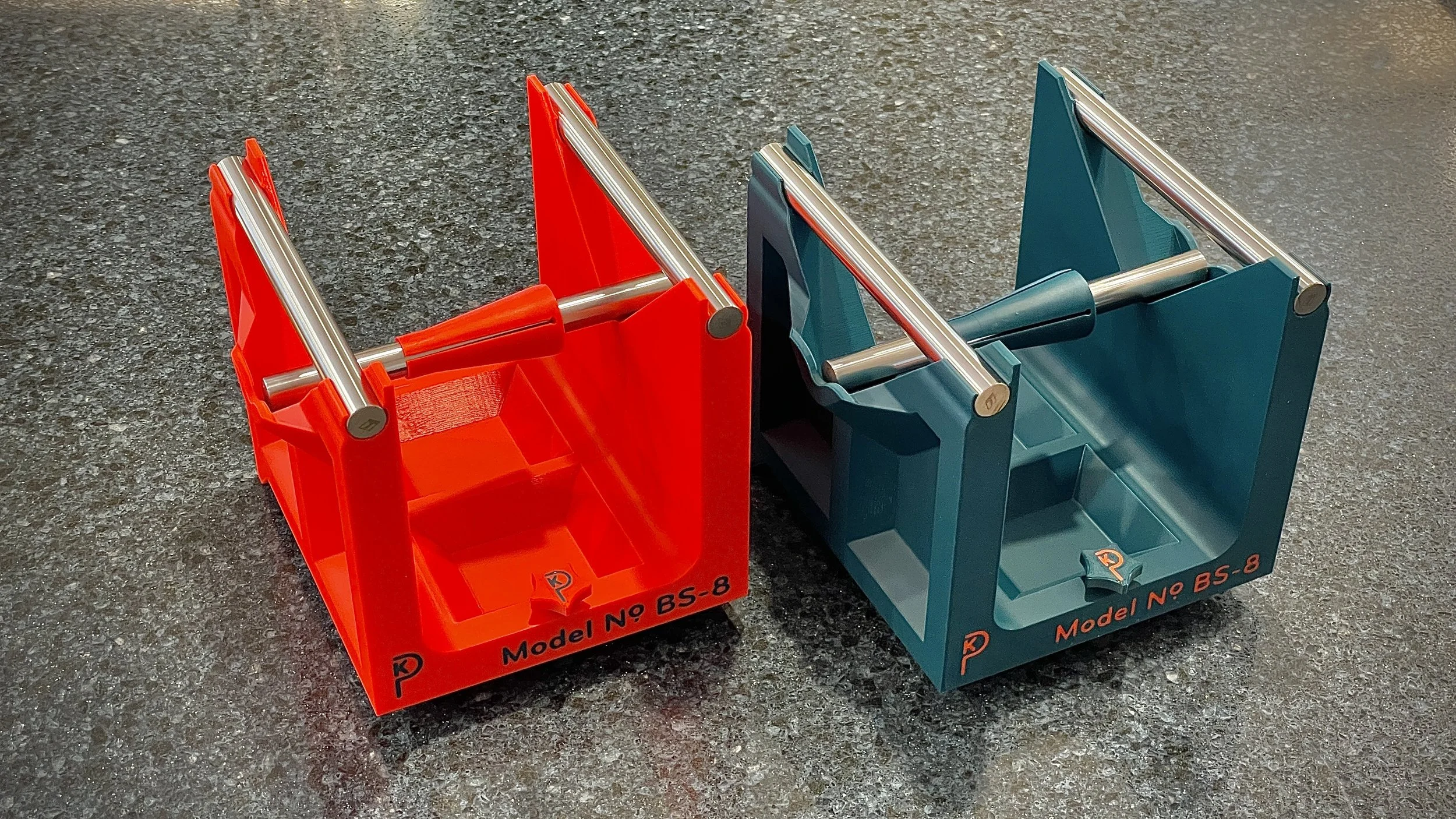

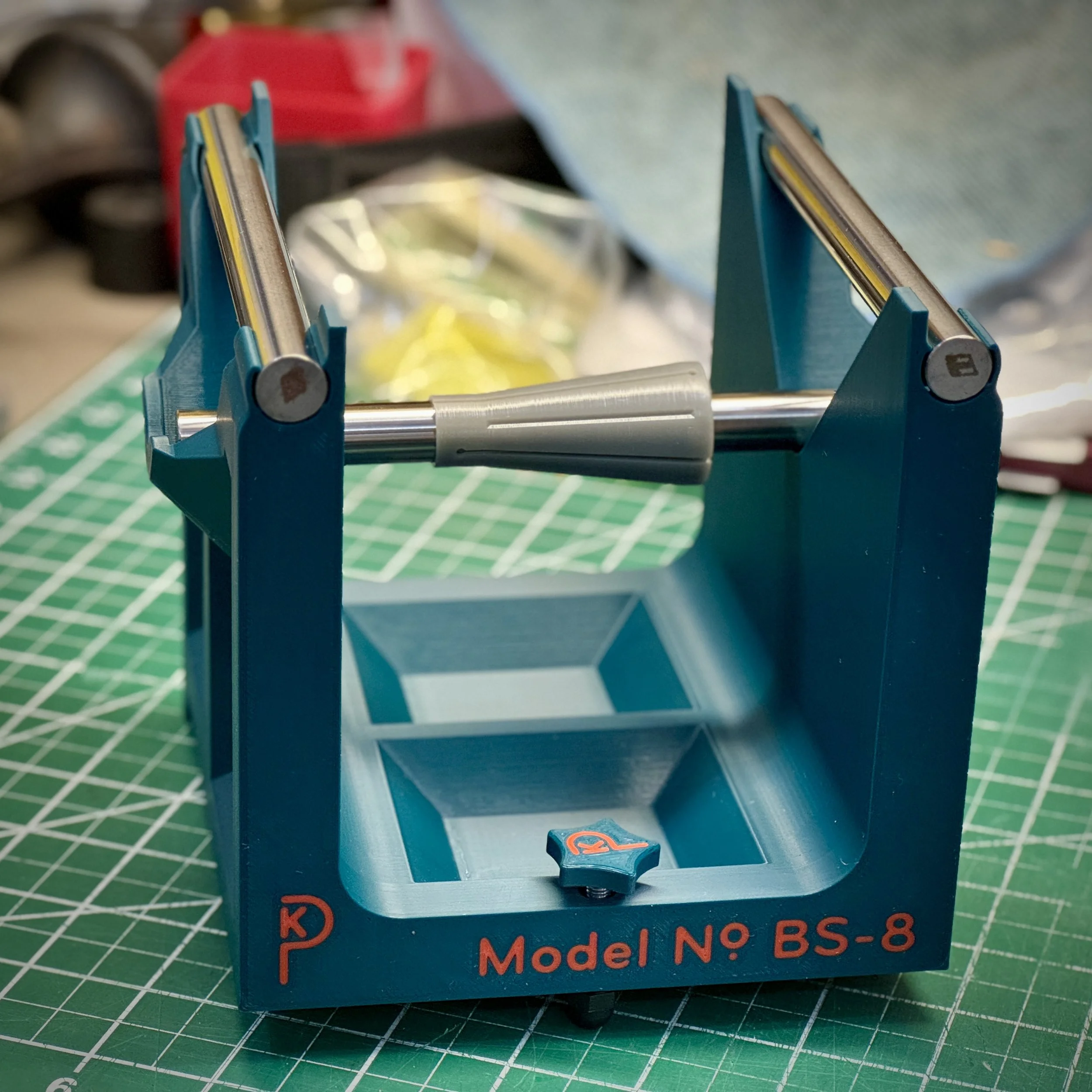

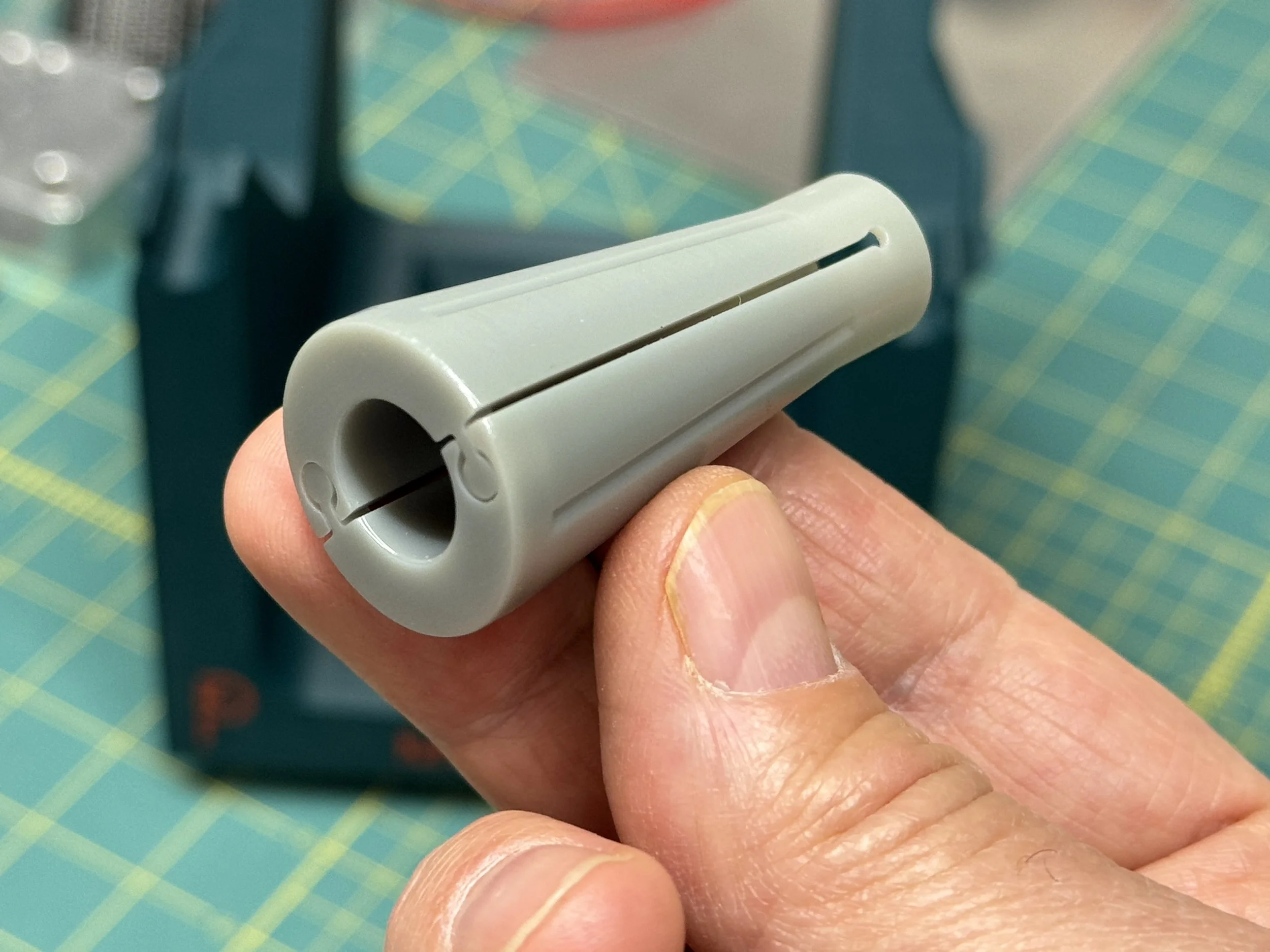

The BS-8 Balancing Stand from Kinetic Precision is designed to enable economical, effective balancing of grinding wheels up to 8 inches in diameter. It comes with a unique taper collet to fit most standard adapters, such as the Sopko 100-, 200- and 300-series.

The BS-8 Balancing Stand is designed to balance wheels up to 8-inches (200mm) in diameter. Sorry, you 12-inch guys aren’t covered with this tool.

The Importance of Balancing Grinding Wheels for Surface Grinders

Maintaining the optimal performance of surface grinders includes one crucial step - balancing the grinding wheels. Neglecting this essential aspect can lead to a plethora of problems that can compromise the entire grinding process.

When grinding wheels become unbalanced, they inflict excessive vibration upon the surface grinder. This vibration can trigger a cascade of issues that have far-reaching consequences on both the accuracy and precision of the grinding process.

Firstly, unbalanced wheels often result in poor surface finish. The irregular distribution of weight within the wheel disallows it from achieving a consistent and smooth contact with the work-piece. As a result, the desired surface finish is compromised, and the outcome becomes inconsistent. This not only undermines the precision of the grinding operation but also jeopardizes the quality of the finished product.

In addition to compromising surface finish, unbalanced wheels can also lead to inconsistent stock removal. This inconsistency has a direct impact on productivity. As the wheel churns through the material, unpredictable variations emerge in the amount of stock being removed. Consequently, the grinding process becomes less efficient, causing delays in production and hindering overall productivity.

However, the repercussions extend beyond mere productivity. The excessive vibration caused by unbalanced wheels strains the machine itself, subjecting it to unnecessary wear and tear. Over time, the repeated exposure to such vibrations can drastically shorten the lifespan of the surface grinder, especially the spindle bearings. This frequent strain poses a significant risk of component failure, leading to costly repairs or, in severe cases, the replacement of the entire machine.

Coming soon:

But, I was told small grinders don’t need to balance wheels

Balancing Rings are also part of the process

PFG Stones® let you see the truth, and at a level beyond your requirements

The BS-8 is Not Perfect

List of all the Errors