PFG Stones® are like magic. These are no ordinary abrasive stones. They are intended to deburr normally-flat precision metal surfaces without harming the original grind.

PFG Stones® are Kinetic Precision’s brand of precision ground flat stones. We’ve been making, selling, and improving them since February 2019. And they are pretty freaking great!

All NFG is removed in the manufacturing process.

We supply these specialty tools to individual toolmakers, precision machinists, watchmakers, instrument makers, researchers, national laboratories, space agencies, manned spacecraft manufacturers, firearms manufacturers, knife makers, moldmakers, high-performance engine manufacturers, racing teams, machine-tool accessory manufacturers, 3D printer manufacturers, computer manufacturers, universities… and more.

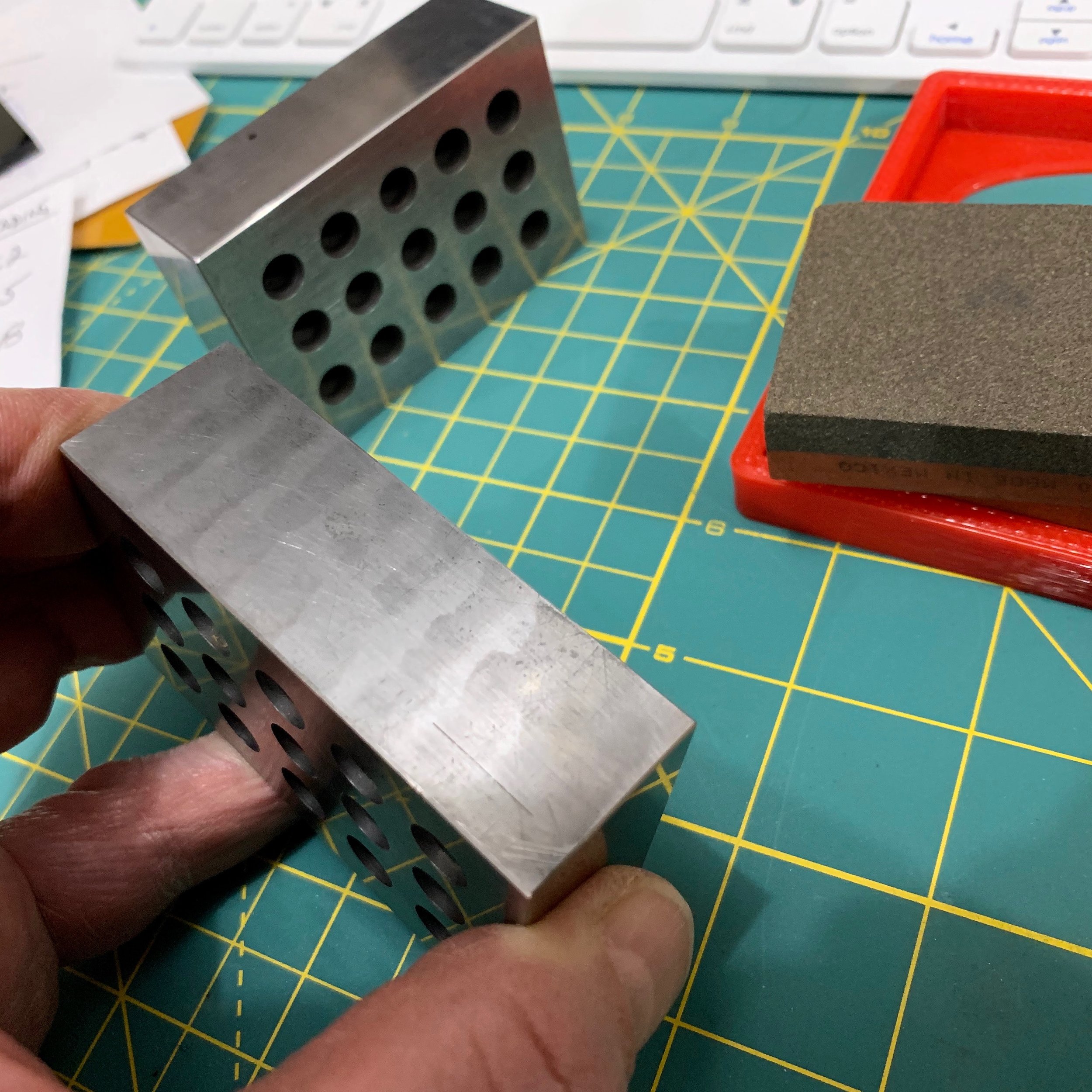

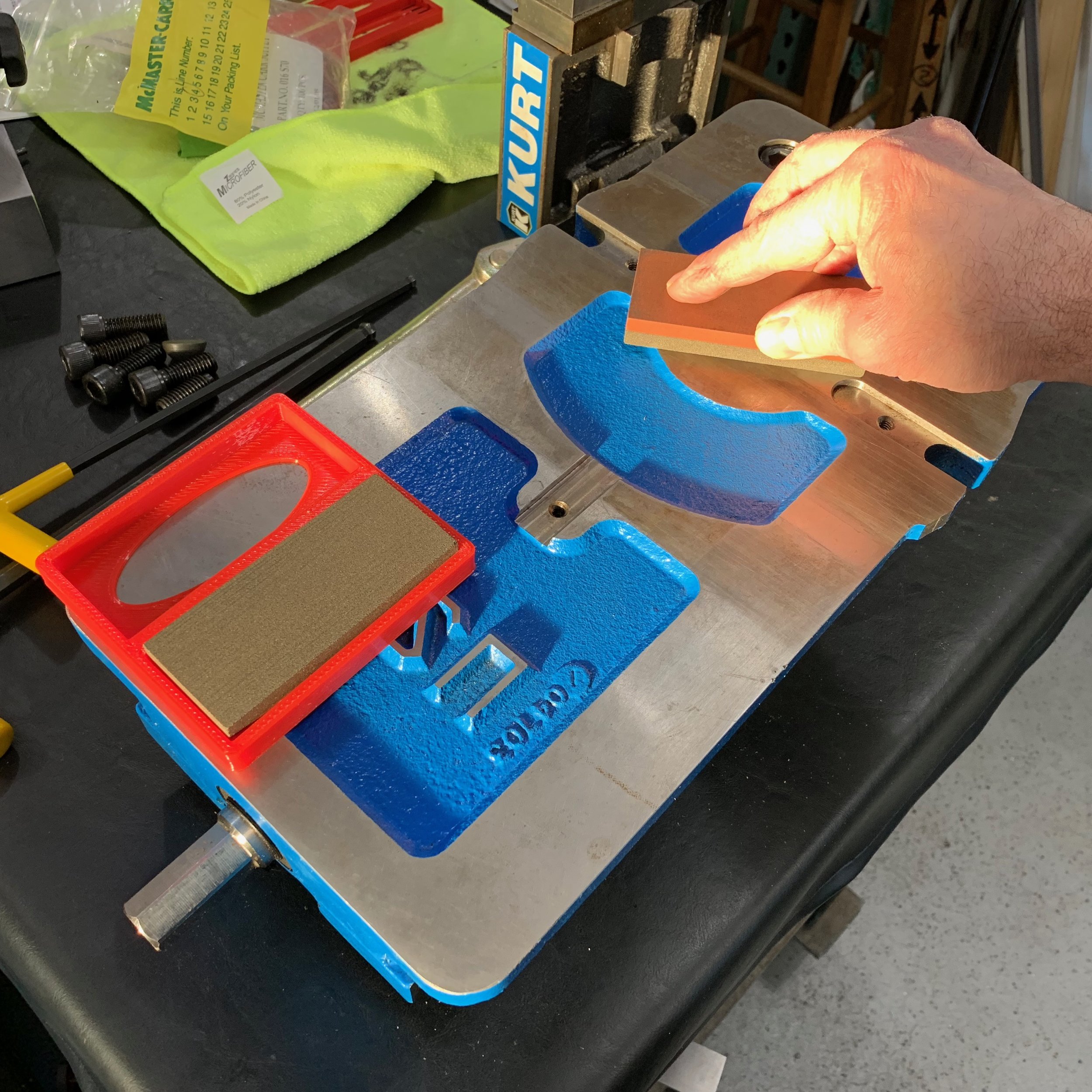

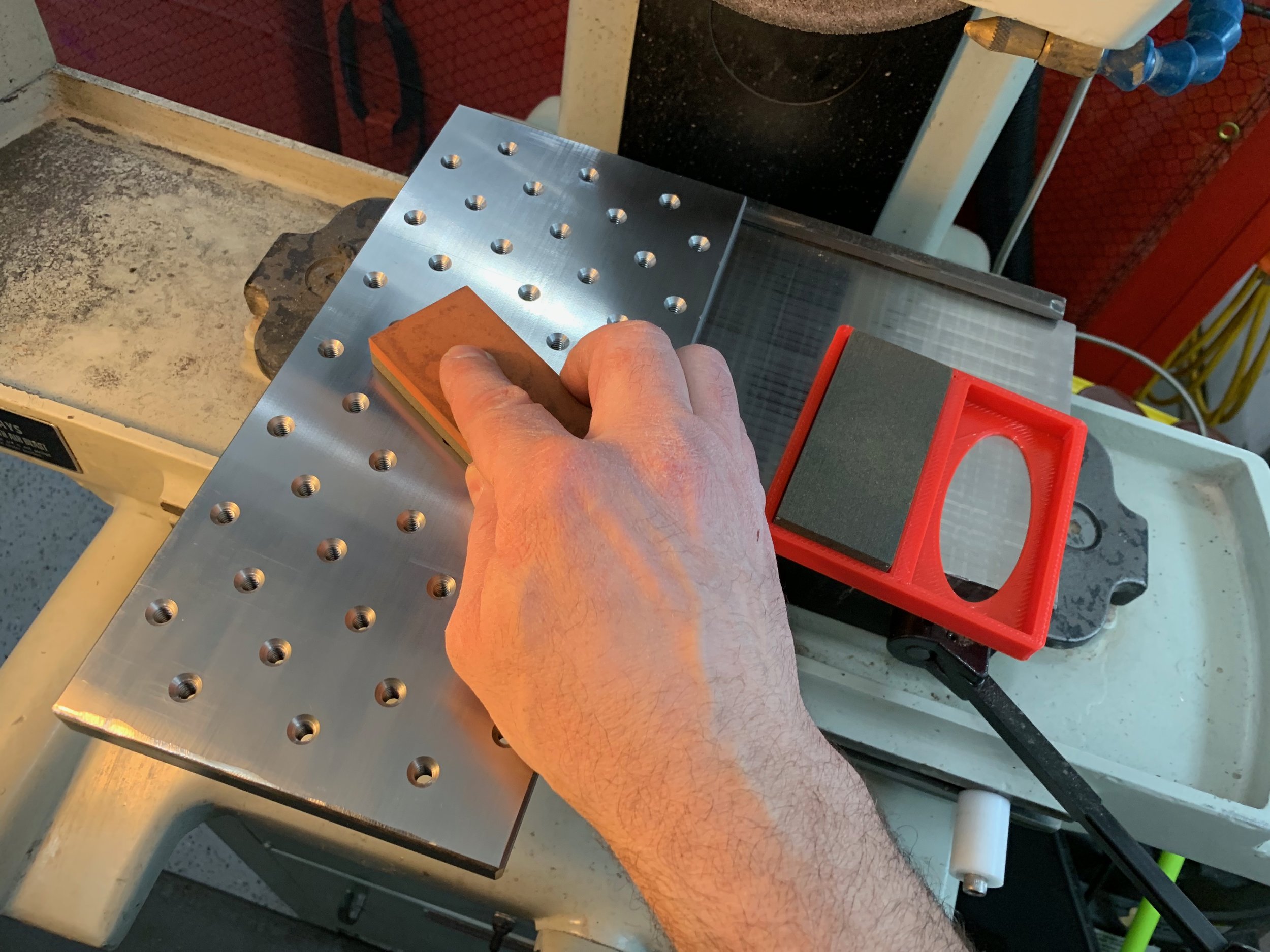

Are you still using out-of-the box stones on your precision surfaces? Seriously?! Did you ever see people using stones out of the box, and being very delicate with them? That’s because they are not flat, and will scratch precision surfaces with any pressure. Use PFG Stones® with significant pressure, and don’t worry, they will not scratch - only deburr (watch our videos, below). If you’re stoning your vices and tables and other precision surfaces, you’re already in the top 10% of machinists. How about joining the top 1%, and do it right?

The four largest surfaces of each rectangular PFG Stones®, faces and sides, are diamond-ground very, very flat to a total flatness better than 50 microinches (0.00005-in.) deviation.

You can use the long sides just like the major faces. We use a metal-bond diamond grinding wheel on our Okamoto 8x18” CNC surface grinder (Model ACC818NC) using our proprietary workholding. Pairs of stones are generally ground together and have the same thickness (not guaranteed). There is no additional processing of the faces after the diamond grinding, except cleaning. The edges are lightly chamfered with a diamond lap. (The two smallest ends of each stone are not ground. Nor are round sides of the round stones.)

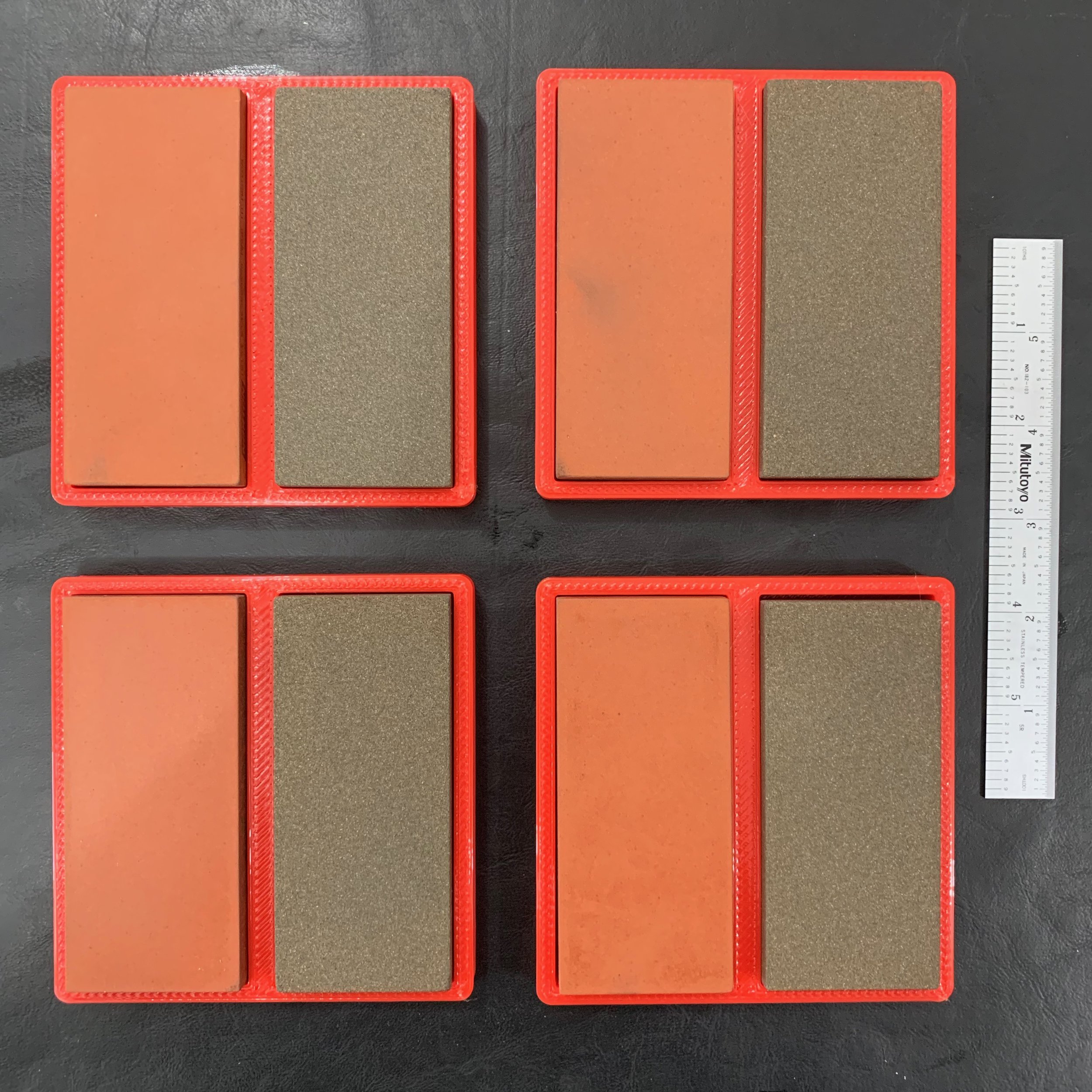

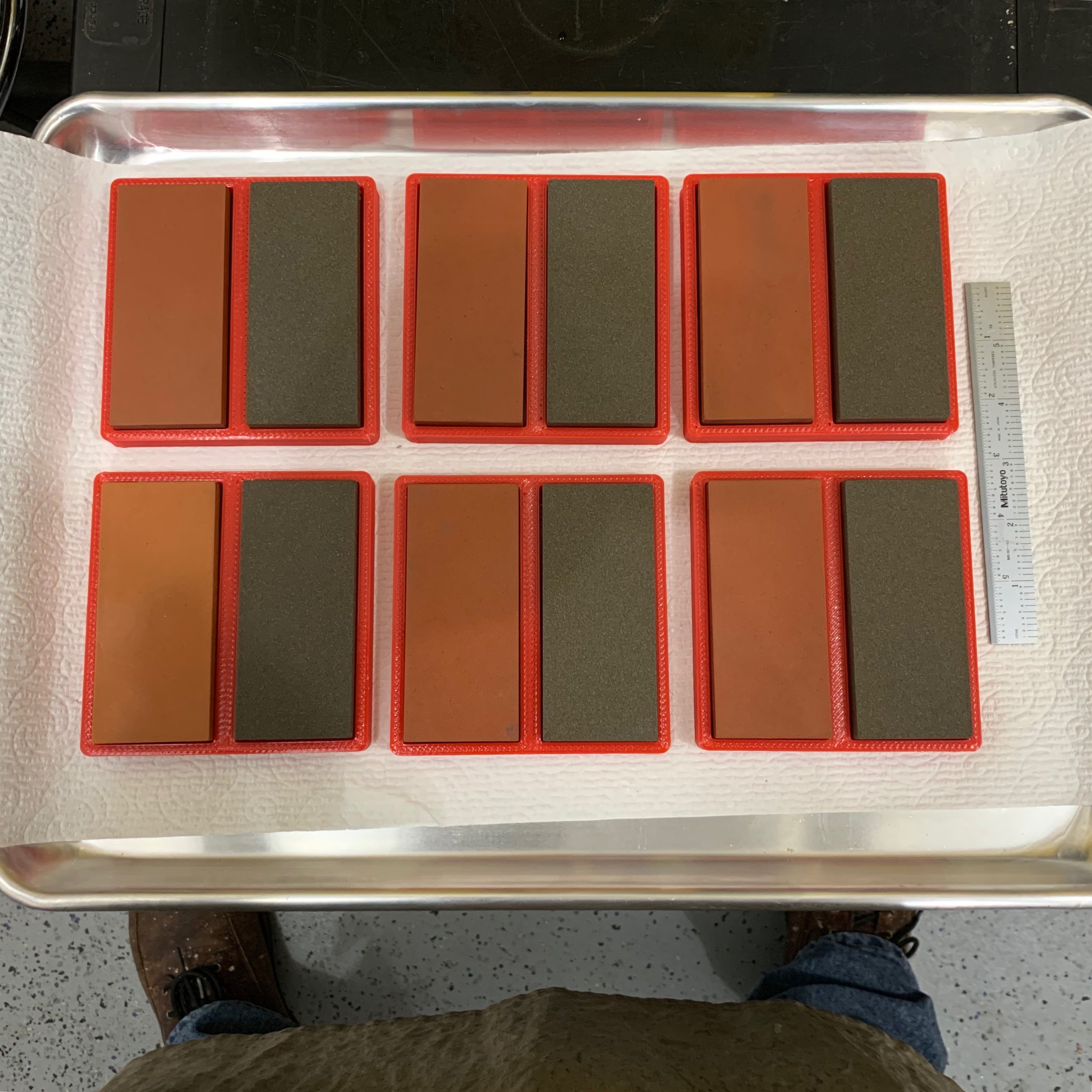

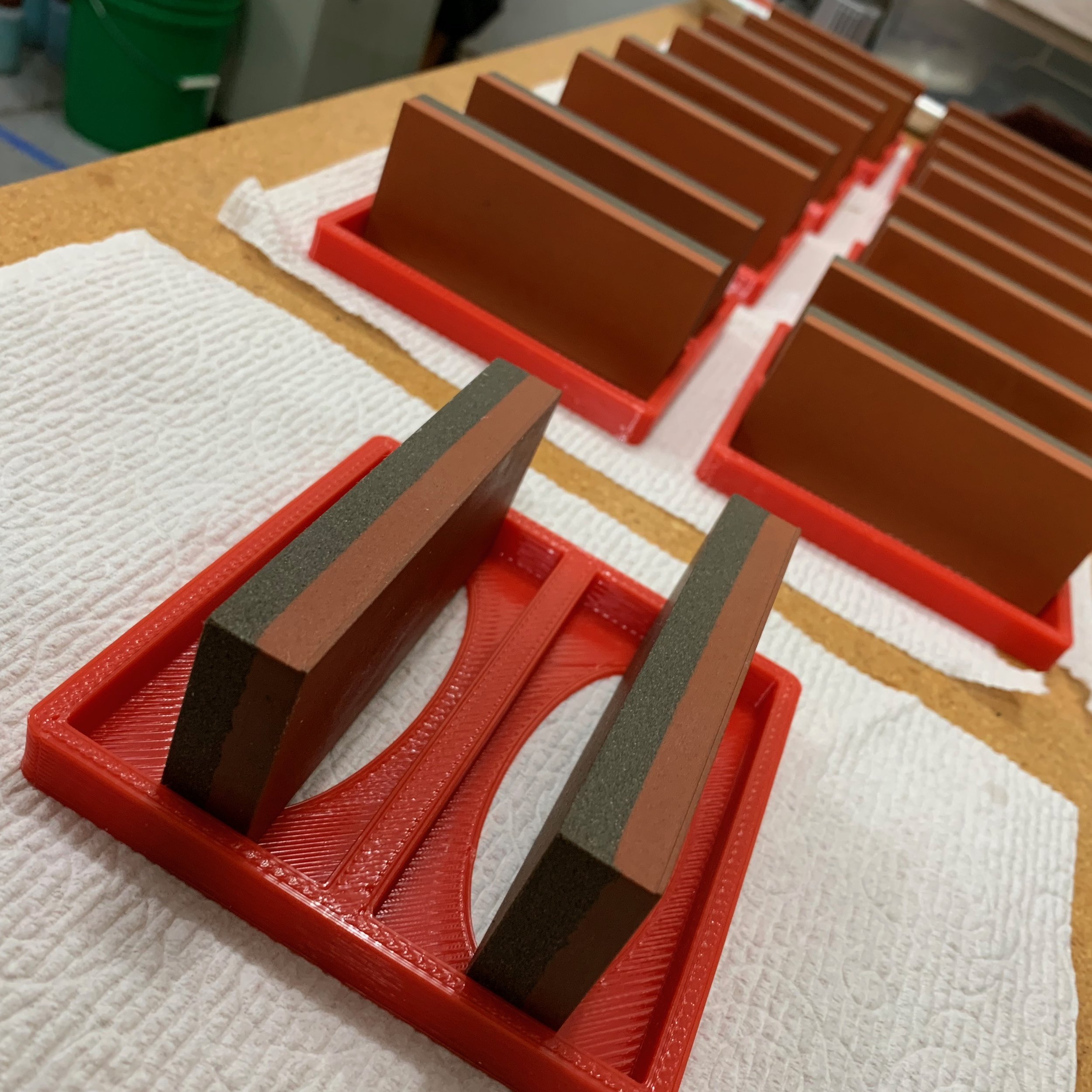

All the PFG Stones® are dual-grit, except the MINIs (PFGS-4M), in which there is one “coarse” stone and one “fine” stone.

PFG Stones® are laser-marked (when possible) on the sides. This results in a slightly sub-surface mark. We never mark the precision major working faces of your PFG Stones®. And we would NEVER use an ink marking, proud of the surface, which would prevent the precision use of one side!! (Why would you do that?!? Yep, we measured 0.002” thick ink on one brand.)

All PFG Stones® are washed in soap and water, dried, and rinsed in Denatured Alcohol prior to shipping.

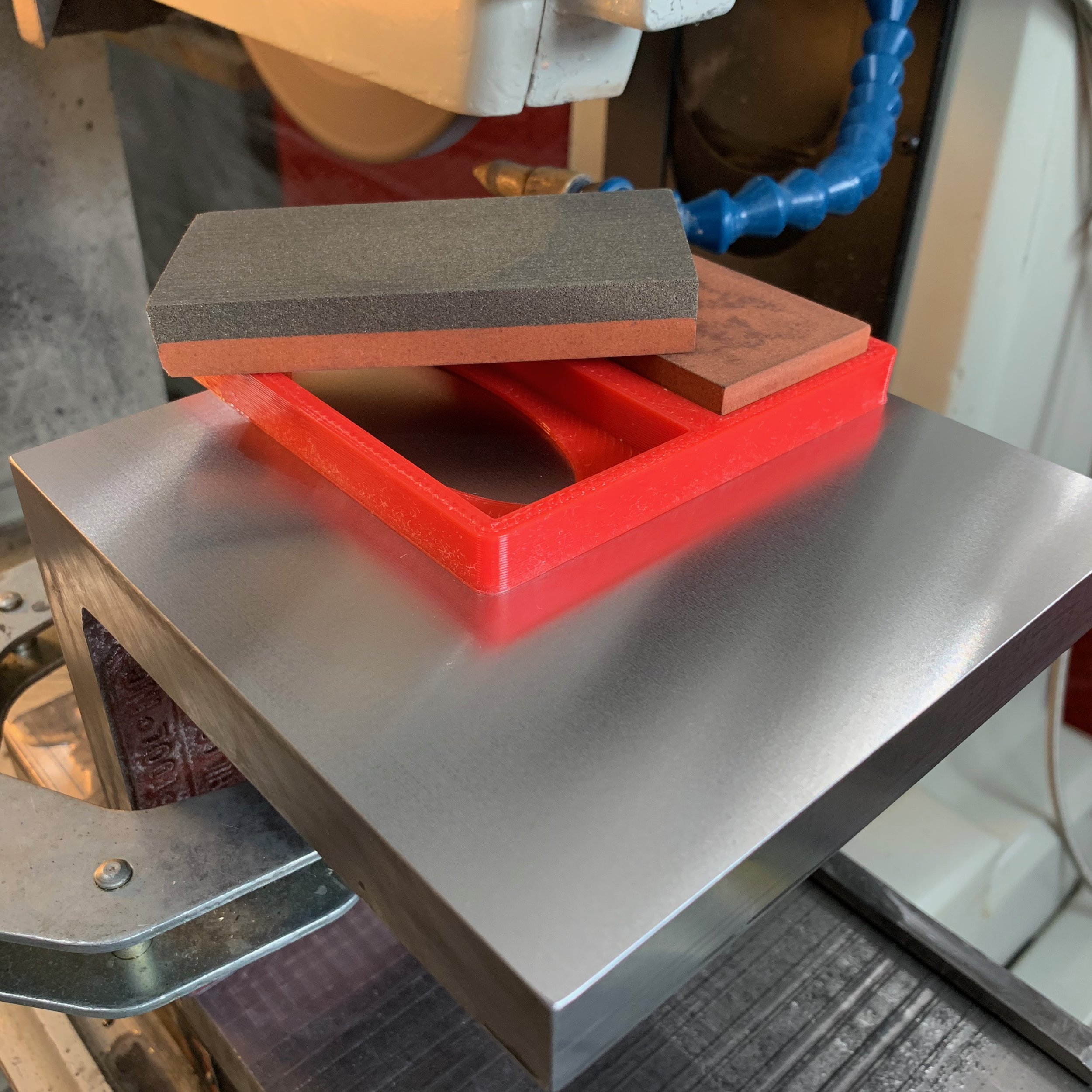

All PFG Stones® are supplied in our trademark red dual-trays. These trays are very functional AND take up minimal space in your toolbox or storage drawer. Lids are optional, but they help keep your stones clean and protected. The trays are open on the bottom surface so that debris can find its way out. We do not use fancy ornamental boxes because these are working tools, and the space in your shop is valuable!

All raw materials are USA-sourced from Norton (most are marked as having been manufactured in Mexico by Norton).

The Model PFGS-4 aluminum oxide stones each have nominal dimensions are 5/8" thick x 1-3/4 x 4 inches. Each stone weighs 173 grams (6.1 oz.).

The Model PFGS-4M MINI aluminum oxide stones each have nominal dimensions of 1/2" thick x 1 x 4 inches. Each stone weighs 86 grams (3.0 oz.).

The Model PFGS-4R aluminum oxide round stones each have nominal dimensions of 4-inches in diameter and one inch thick. Each stone weighs 496 grams (17.4 oz.).

The Model PFGS-4RC silicon carbide round stones each have nominal dimensions of 4-inches in diameter and 1-1/2 inch thick, with finger grooves. Each stone weighs 500 grams (17.6 oz.).

The Model PFGS-6 aluminum oxide stones each have nominal dimensions of 1" thick x 2 x 6 inches. Each stone weighs 476 grams (16.8 oz.).

The Model PFGS-8 aluminum oxide stones each have nominal dimensions of 1” thick x 2 x 8 inches. Each stone weighs 634 grams (22.4 oz.).

The aluminum oxide stones have a fine side of 320 grit, the coarse side 100 grit. The silicon carbide stones have a fine side of 280 grit, the coarse side 120 grit.

When you first get your set of PFG Stones®, you may notice that they are “oily”. The stones are impregnated with oil when the material is manufactured. Temperature changes during shipping tend to bring the oil to the surface. You can wash the stones in water with a mild detergent (Dawn for example), or use Denatured Alcohol (Ethanol, mostly) or Isopropyl Alchohol (IPA, not the beer). In the final steps of our PFG Stones® production process, we use a water-detergent wash, and a final Denatured Alcohol bath.

Yes, we ship internationally!!

PFG Stones® have been shipped to over 19 countries, so far, and counting…

We ship internationally via DHL Express Worldwide. Please carefully review our shipping page.

Use PFG Stones® on:

Magnetic chuck surfaces prior to putting parts on

Part surfaces prior to putting on magnetic chuck

Machine ways

Deburring during hand scraping

Flat-ground surfaces prior to putting on a surface plate or another ground surface

Toolholder tapers (CAT-40, etc.)

Collet tapers (ER-32, etc.)

For more thoughts on application of PFG Stones®, see our Applications video, also linked below.

“When should and shouldn’t you use PFG Stones®?”

The short version is: “If it was originally made flat, use the PFG Stones® on it. If you’re trying to make it flat, use a different method first.” (Cylinders and tapers are included, as they are flat in one dimension. They require some technique.).

“Can I break a sharp edge?” It wasn’t made flat, use a better tool. You may prematurely wear your PFG Stones® breaking edges. Yes, you can move the stone perpendicular to the corner, but use extreme caution.

“Can I stone my Kern milling machine table?” It was made flat, so yes. (Or vise jaws, vise floor, tooling block, machine ways, etc.) (See Grimsmo Knives video, below)

“Can I use it to point my TIG welding tungsten?” Oh, hell no! Just stop.

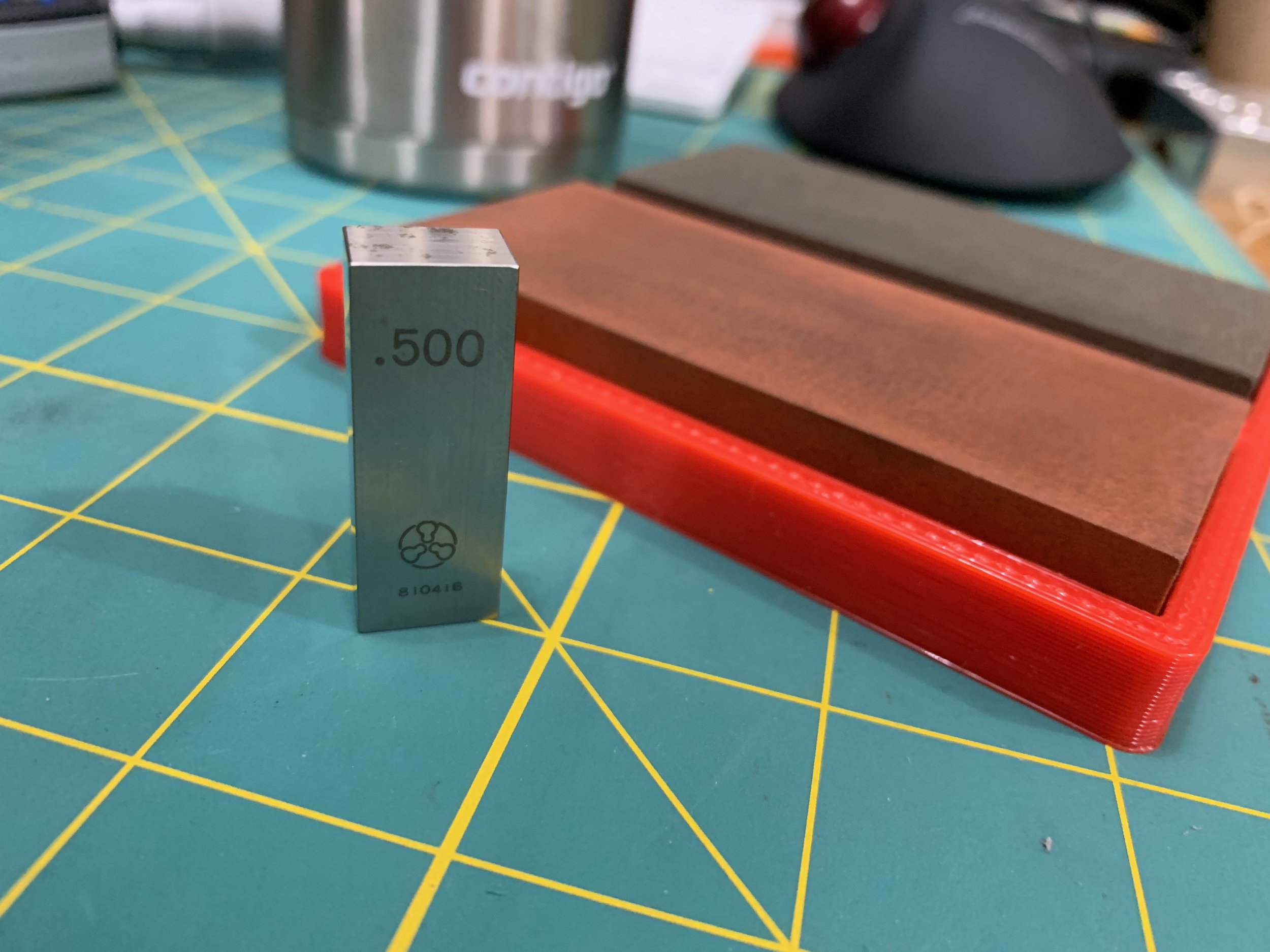

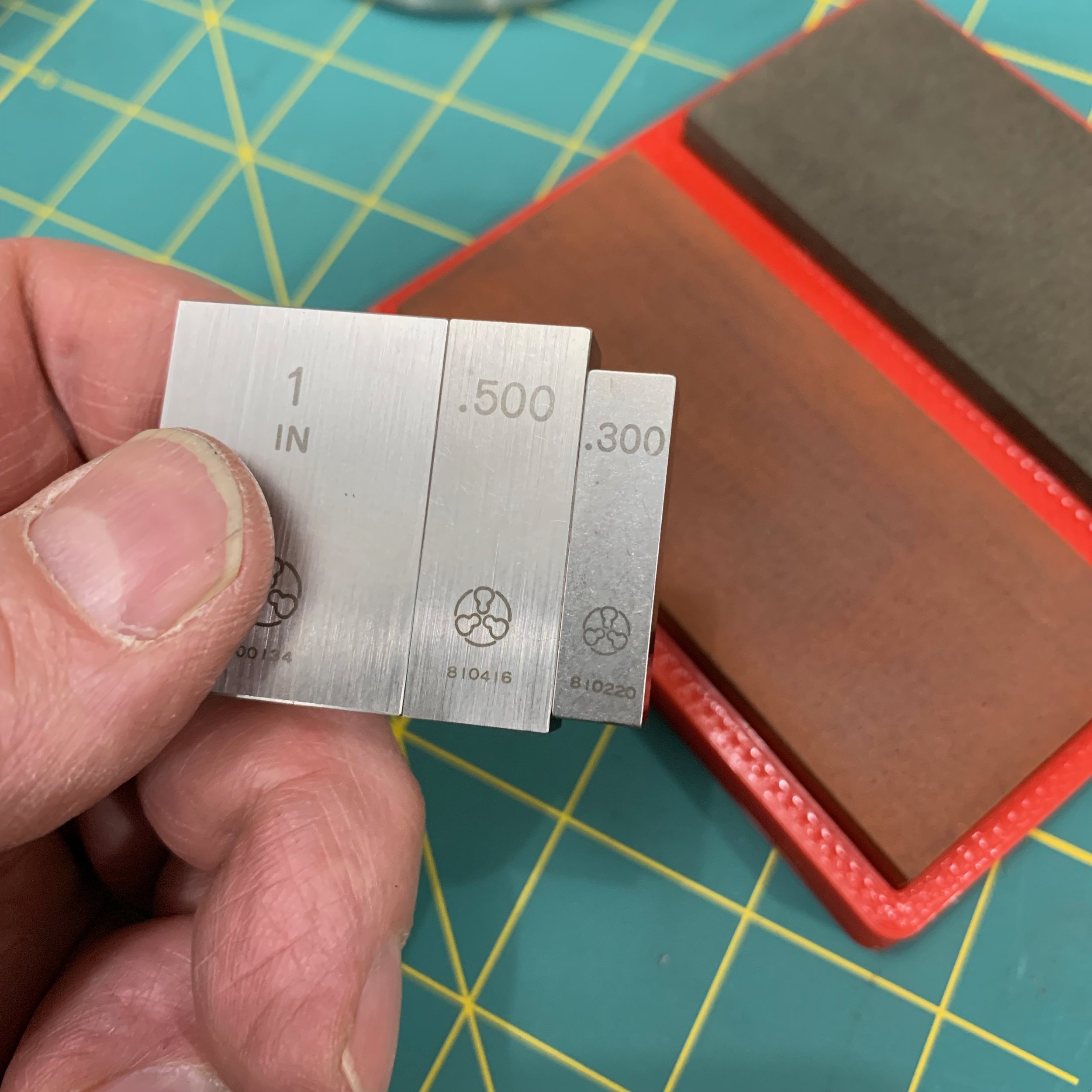

“Can I clean my gage blocks?” Actually, yes. Use the fine side. Two strokes may be all you need. See our videos for an example.

“I want to deburr all my aluminum projects!” Aluminum is very soft, and will likely smear with the application of PFG Stones® rather than chip. This tends to load up the stone and require cleaning. If you must use them on aluminum, use the coarsest side (Brown on the aluminum oxide stones.) The fine side (orange) can load up with aluminum beyond the ability of normal cleaning methods to remove it. See below for more information on aluminum.

If it was originally made flat, use the PFG Stones® on it. If you’re trying to make it flat for the first time, use a different method.

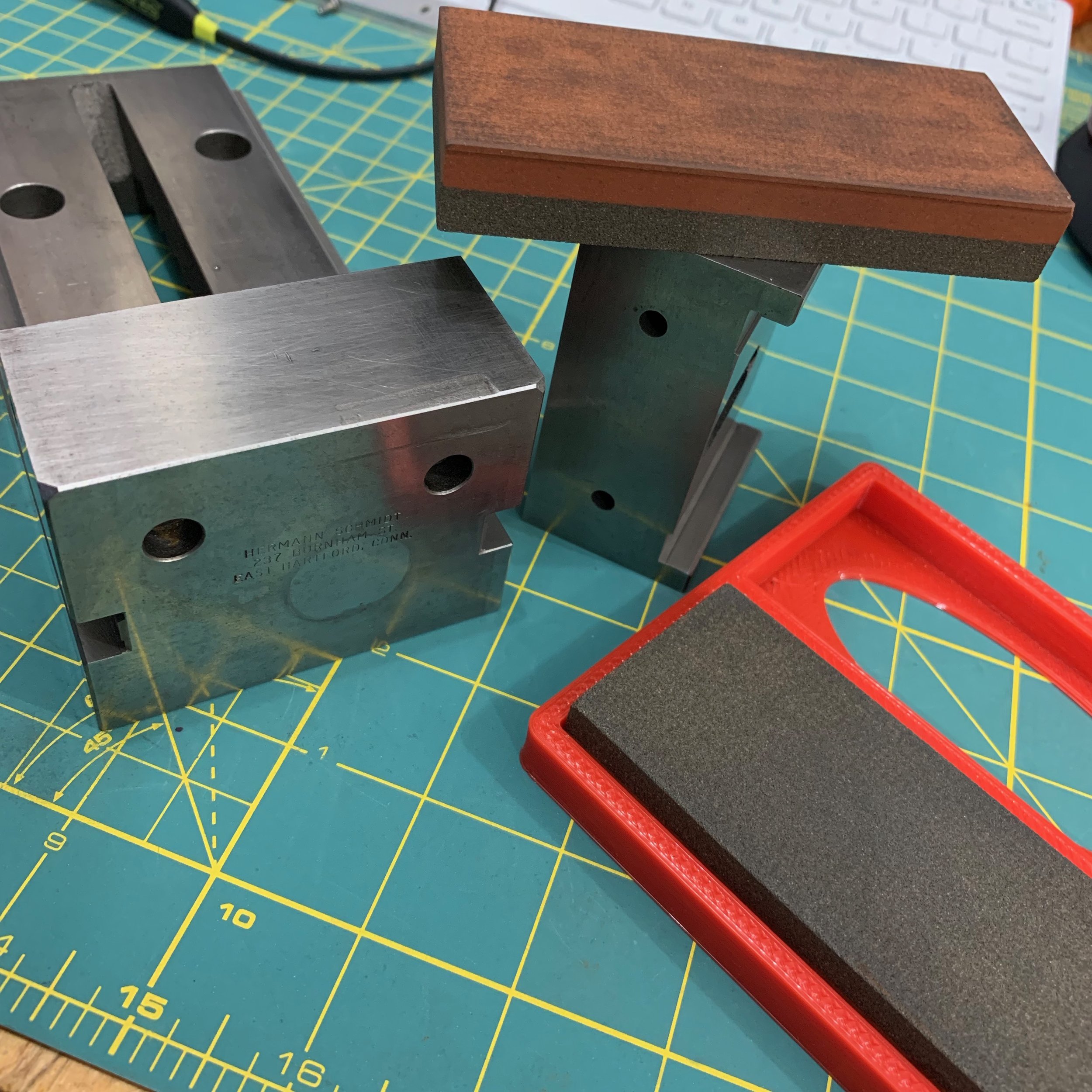

When you first get your PFG Stones®, and every time prior to using them, rub the “working” stone on the “conditioning stone”. Don’t be afraid to use pressure, five pounds will not hurt. You will feel and hear surface condition, and you’ll notice the stones get smoother in a few seconds. This is the foreign particles being worked out, and the surface getting smoother. Once this happens, you can transfer to the work.

Notes on using your PFG Stones®:

We pack our products wrapped with foam. Please report any damage to your PFG Stones®. We do our best to pack them, but the shippers can be pretty clever. We want your PFG Stones® to arrive PFG.

You may notice that the stones are “oily”. The stones are impregnated with oil when the material is manufactured. Temperature changes tend to bring the oil to the surface. You can wash the stones in water with a mild detergent (Dawn for example), or use Denatured or Isopropyl Alchohol.

Watch our video at the bottom of this page demonstrating how PFG Stones® are used. See also the other useful links at the bottom of this page.

Keep your stones in the tray when not in use. The “cleaning” stone can stay in the tray during use.

DO rotate and randomize your PFG Stones®. Use either one for “working” or “cleaning”, and switch them up.

BOTH sides are diamond flat-ground and PFG! The aluminum oxide stones have a fine side of 320 grit, the coarse side 100 grit. The silicon carbide stones have a fine side of 280 grit, the coarse side 120 grit. The long sides are also flat-ground, with the same recipe as the faces. The edges are all deburred. The small ends are not flat-ground. Grinding of a lip on one or both sides is available as an option at additional cost.

Clean your stones with a toothbrush (or similar) and isopropyl alcohol (McMaster 3190K812). They work just fine when they are amazingly dirty, but what if guests show up?

In the supplied tray, keep one PFG Stone fine side up, and the other coarse side up. If, for example, you want to use the fine side, you only need one hand to pick up the stone which is fine side down and clean it on the other stone. And you can put it back in the tray and store it with one hand. You won’t believe how useful this is.

We recommend using your PFG Stones® on steels, cast iron, titanium, and other harder materials. Use caution on aluminum. Aluminum is very soft, and will likely smear with the application of PFG Stones® rather than chip. This tends to load up the stone and require cleaning. If you must use them on aluminum, use the coarsest side (Brown on the aluminum oxide stones.) The fine side (orange) can load up with aluminum beyond the ability of normal cleaning methods to remove it. We think that sodium hydroxide (NaOH) may be a good way to clean PFG Stones® of aluminum, but we’ve not definitively tested that yet. Aluminum can be dissolved by strong NaOH solutions. Use caution.

If you ordered your stones with a LIP, please transport them in the tray with the lipped side UP. This will keep the lip from striking the edge of the tray cavity and chipping.

Always clean the surface you are about to stone! You can greatly reduce the need to clean the stones by following the simple rule. You may hear this advice again, soon.

Instructions for use

Clean the work before applying the stones. Any oils or grease are going to be picked up by the stones, and cleaning will be needed sooner. We wipe with Denatured Alcohol.

Rub two stones against each other to remove particulates on the stones. You’ll feel and hear them get clean. Check the surface with a wipe of your hand, your “sensors” are invaluable.

Carefully apply one stone to the work and rub with light pressure. You will feel any burrs and the general surface condition.

If loose particulates can be felt, stop and go to Step 1. These will interfere with you sensing the burrs, and may scratch the surface.

Continue stoning with moderate pressure until the work feels smooth.

Look for bright spots on the work which indicates the bearing surface. If there are no identifiable bright spots, your work is very flat!

Periodically clean your PFG Stones®. You can use the WD-40 and carboard technique, shown below. Or use an ultrasonic cleaner with an anionic detergent solution. We use LPS Precision Clean (1:10 dilution). Rinse in clear water and allow the stones to air dry completely before use. Isopropyl alcohol (99%) or Denatured Alcohol (Mostly Ethanol with some Methanol) and a toothbrush works well, too, for routine cleaning.

Thank you for your business. PFG Stones® are made to order. Lip grinds are available upon request, at additional cost.

These are precision instruments, please take good care of them and they will give you a lifetime of faithful service. And they'll listen to your bad jokes without complaints.

How to Clean Grungy PFG Stones®

We discovered a technique which we’d been talking about for a couple of years, but finally found out how fantastic it really is. What do you do when your PFG Stones® get grungy from many hours of use? Above we talked about solvents, soap and water, brushes, and ultrasonic cleaners. But, the most efficient and effective way we’ve seen yet is <drum roll> WD-40 and cardboard. Yep, that can of regular WD-40 and a piece of that corregated-cardboard from the shipping box you are about to discard. Watch the video below…

It couldn’t be simpler, or faster. You can use a solvent to clean up afterwards, if you’d like. We could not be happier with the results. Enjoy!

On Stoning Gage Blocks

Cylo’s Garage did a deep dive into stoning gage blocks.

BEVELS!!

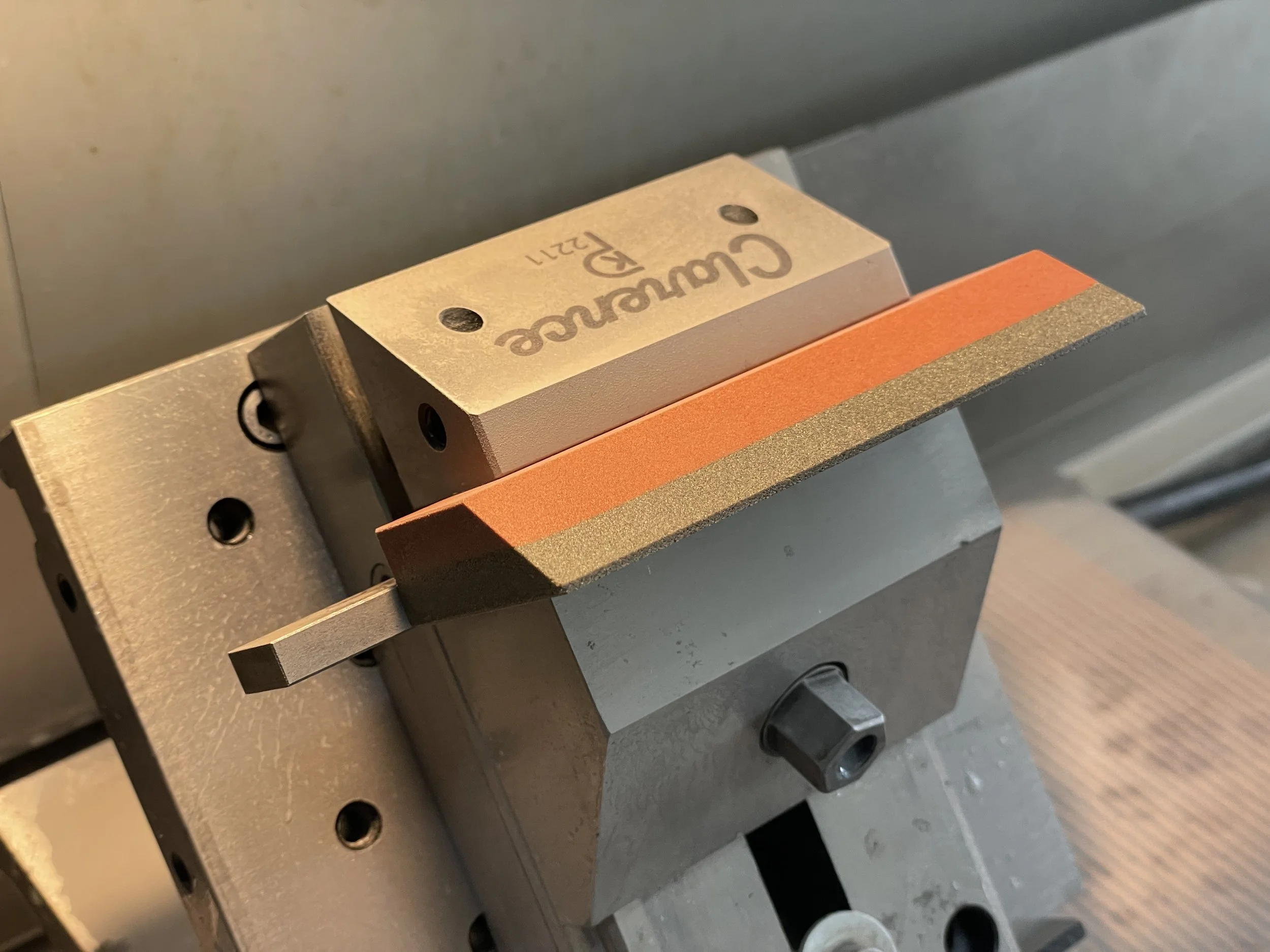

Yes, you can get bevels cut on your stones. We can cut one bevel on each stone, ordering details are in the Purchasing section. Here is what they look like…

This is “Cut Fine, Coarse Intact”.

This is “Cut Fine, Coarse Intact”. (That label is called a “traveller”, and is generated with your bevel order. It follows your order through the process to insure accurate manufacture.)

This is “Cut Coarse, Fine Intact”

This is “Cut Coarse, Fine Intact”

The normal angle is 40-degrees. The normal “flat” on the point of the bevel is 0.050” high. One bevel per stone.

NOTE: At present, bevels are only available on PFGS-4, -6 and -8. (Not on the MINIs… sorry)

How do PFG Stones work?

The photomicrograph on the left is a 100-grit Norton stone, unmodified, straight out of the box. The image on the right is the same type stone after the proprietary diamond-grinding procedure. The field is 4mm across. (Click to enlarge the image.)

Note that the abrasive grains in the original stone, on left, are ragged and not coplanar. This stone will scratch a precision surface with little pressure. It is designed to remove material, and it will. This is the raw material for the PFG Stones®.

The stone on the right has been diamond-ground flat to better than one-tenth of a thousandth of an inch (0.0001”) over the stone. The grains at the surface are now coplanar, yet the porous structure behind the plane is still present. This is where the material goes when a work-surface protrusion is cut by the stone. Yet, on a flat surface, at normal pressures, no cutting action can take place. This stone will not scratch a precision surface, but it will improve it.

The finer-grit side of the PFGS-4 stone is 320-grit, and is harder to photograph, but the principle is the same. It will have less volume for removed material.

The pattern seen in the photo on the right is similar to a precision scraped surface. In scraping, a surface has “plateaus” which are made coplanar and flat. Between the plateaus, there is a depression which holds oil and perhaps minor debris. This allows a scraped surface to have an excellent sliding bearing. A PFG Stone is directly analagous: it has “plateaus” which are ground (not scraped), and recesses for the debris. The edge of each plateau will cut a burr protruding from a flat surface, but otherwise it will just slide.

Here is an artist’s (!?) rendition of the grinding process, using PenCAD and scissors.

This is the magic of PFG Stones®.

VIDEOS!….

(Also, watch the video playlist here.)

What are PFG Stones®? In this video, we learn the fundamental operation of the stones, and how they deburr a flat surface.

Applications for PFG Stones®, and when NOT to use them. 20 minutes, one take, no waiting…

John Grimsmo talks about his PFG Stones® for about five minutes, starting at timestamp 38:38. (Click here to go directly to that timestamp in separate window.)

In this video, Yuchol talks about his PFG Stones® starting at timestamp 20:43… (Click here to go directly to that timestamp in separate window.)

Notes and Useful Links:

Here is an excellent article by Tom Lipton about precision ground flat stones.

Here is a video by Tom Lipton about cleaning stones.

Here are instructions by Starrett about how to stone gage blocks. You may use the fine PFG Stones® for this purpose.

An excellent brief paper: Marsh, Eric. Repairing a Damaged Part with Flat Stones, Penn State University. Originally from: <http://mdrl.mne.psu.edu/docs/flatstones.pdf>, recovered from the Internet Archive for your convenience. Date of publication unknown. In this brief, Dr. Marsh refers to work by Melvin J. Liebers in 1997 on the use of precision ground flat stones in the repair of precision surfaces. (Dr. Eric Marsh CV)

See also Robin Renzetti’s video on Precision Ground Flat Stones.

See also the excellent interview with Mel Leibers of Professional Instruments Company, who recalls the first time he rubbed two precision stones together. We credit Mr. Leibers with the invention of “conditioning” the stones, and thus the concept of stone pairs. Thank you to Cylo’s Garage for this excellent history lesson.

Order PFG Stones® here. All about Shipping and Payments here.

Watch the video playlist here. Our YouTube channel is here.

The KP logo is a trademark of Kinetic Precision. “PFG Stones®” is a Registered Trademark of Kinetic Precision. First used in commerce February 2019.

Two precision ground stones in a red dual-tray is a trademark of Kinetic Precision. “NOZ” and “Perfect Fluid Guide” is a trademark of Kinetic Precision.

updated 17 JAN 2026